The post Detecting faulty boiler heat exchanger symptoms appeared first on Heat Quick Direct.

]]>Understanding faulty heat exchangers

A faulty boiler heat exchanger can cause significant problems in your home, ranging from decreased heating performance to dangerous levels of carbon monoxide. Understanding what a heat exchanger is, what can cause it to malfunction, and what steps to take if you suspect a problem can help you stay ahead of the issue and keep your home safe and warm.

In this comprehensive guide, we’ll explore the basics of heat exchangers, including how they work, what they are made of, and where they are located within your boiler. We’ll also discuss the most common signs of a faulty heat exchanger, from strange noises to increased levels of carbon monoxide. Finally, we’ll outline the steps you should take if you suspect a problem, including how to turn off your boiler, when to call a professional, and what to expect during the inspection and repair process.

Whether you’re a homeowner or a heating engineer, this guide will provide you with the information you need to understand and troubleshoot faulty boiler heat exchangers. So if you’re looking to stay informed and stay ahead of the problem, read on to learn everything you need to know about faulty boiler heat exchangers.

What is a Boiler Heat Exchanger?

A heat exchanger is a component of your boiler that plays a vital role in the heating process. It is responsible for transferring heat generated by the combustion of fuel (natural gas, oil, or propane) to the water used for heating. The heat exchanger is usually made of metal and is located inside the boiler.

How Does a Heat Exchanger Work?

The heat exchanger works by using the heat produced during the combustion process to heat the water. This process takes place within the heat exchanger’s metal walls. The heat exchanger acts as a barrier between the combustion gases and the water, preventing the two from coming into direct contact. Instead, the heat is transferred from the hot gases to the water, warming it.

The Importance of a Heat Exchanger

The heat exchanger is an essential component of your boiler system. Without it, the heat generated during the combustion process would not be transferred effectively to the water, resulting in a decrease in heating performance. Additionally, a faulty heat exchanger can pose a safety risk, potentially leading to carbon monoxide leaks.

Signs of a Faulty Boiler Heat Exchanger

A faulty heat exchanger can lead to a number of problems that can negatively impact the performance and safety of your boiler system. It’s important to be aware of the signs of a malfunctioning heat exchanger and to take prompt action if you suspect that there is an issue.

Strange Noises

If you hear loud banging or clanging coming from your boiler, it could be a sign of a faulty heat exchanger. This could be a result of metal expansion or contraction, which can cause the heat exchanger to rub against other components in the boiler.

Decreased Heating Performance

If your boiler is no longer heating your home effectively, it could be due to a faulty heat exchanger. The heat exchanger is responsible for transferring heat from the combustion process to the water used for heating, so if it’s not functioning properly, your home will not receive the heat it needs.

High Carbon Monoxide Levels

A faulty heat exchanger can cause carbon monoxide to leak into your home, which can be extremely dangerous. Carbon monoxide is a toxic gas that is odourless, colourless, and tasteless, making it difficult to detect. If you have a carbon monoxide detector, pay close attention to its readings and take action if the levels are elevated.

Water Leaks

A leak in the heat exchanger can cause water to leak from your boiler. If you notice any water near your boiler, it’s important to have it inspected promptly. A leak in the heat exchanger can cause serious damage to your boiler and other components in your heating system.

What to Do If You Have a Faulty Boiler Heat Exchanger

If you suspect that your heat exchanger is faulty, it’s important to have it inspected and repaired as soon as possible. Here are the steps you should take:

Step 1: Turn off your boiler

The first and most important step in addressing a suspected faulty heat exchanger is to turn off your boiler. This is done to prevent further damage to the unit and to ensure your safety. If you are uncertain how to turn off your boiler, consult the owner’s manual or call a professional heating engineer for assistance.

Step 2: Call a professional heating engineer

You should never attempt to repair a faulty heat exchanger yourself as it requires specialized training and equipment. Instead, it’s best to call a professional heating engineer who is trained and experienced in boiler repairs. They will be able to diagnose the problem and determine the best course of action.

Step 3: Inspection of the heat exchanger

The heating engineer will inspect the heat exchanger to determine if it is indeed faulty. They may use tools such as a carbon monoxide detector to determine if there are any leaks. This step is crucial as it will provide a clear understanding of the extent of the problem and the necessary repair or replacement measures.

Step 4: Repair or Replace the heat exchanger

If the heat exchanger is found to be faulty, the heating engineer will repair or replace it as needed. This will involve removing the old heat exchanger and installing a new one. It’s important to use a high-quality replacement heat exchanger that is compatible with your boiler.

Step 5: Test the system

After the heat exchanger has been repaired or replaced, the heating engineer will test the system to ensure that it is functioning properly. They will check for leaks and make any necessary adjustments to ensure that your boiler is working efficiently. Once they have confirmed that the system is functioning correctly, they will turn it back on and demonstrate how to operate it.

Conclusion

In conclusion, a faulty boiler heat exchanger can have serious consequences, including decreased heating performance, high carbon monoxide levels, and water leaks. Understanding the signs of a malfunctioning heat exchanger is crucial in ensuring the safety and efficiency of your heating system.

If you suspect that your heat exchanger may be faulty, it’s important to take the necessary steps to have it inspected and repaired by a professional heating engineer. By taking the right precautions, you can prevent any further damage to your heating system and ensure that it continues to provide warmth and hot water to your home.

For high-quality and reliable heat exchanger repairs, consider Heat Quick Direct. Our team of experienced heating engineers has the expertise and knowledge to diagnose and repair any problems with your heat exchanger. Contact us today to schedule an inspection and put your mind at ease.

The post Detecting faulty boiler heat exchanger symptoms appeared first on Heat Quick Direct.

]]>The post Why energy efficiency matters for homeowners when choosing a boiler appeared first on Heat Quick Direct.

]]>Explanation of the importance of energy efficiency when choosing a boiler

Energy efficiency is an important factor to consider when choosing a boiler for your home. Not only can a more energy-efficient boiler save you money on your energy bills, but it can also have a positive impact on the environment. Energy efficiency can be defined as the ratio between the amount of energy needed to perform a certain task, and the amount of energy actually used. In terms of boilers, the energy efficiency is measured by the annual fuel utilization efficiency (AFUE) rating, which is a standard measurement used to indicate how much of the fuel used by the boiler is turned into heat.

When choosing a boiler, it’s important to consider its AFUE rating, as this can have a significant impact on the overall cost of operating the boiler. The higher the AFUE rating, the more energy efficient the boiler is, and the less fuel it will need to use to produce the same amount of heat. For example, if you have a boiler with an AFUE rating of 90%, it will convert 90% of the fuel it uses into heat, while the remaining 10% will be lost as exhaust. On the other hand, a boiler with an AFUE rating of 60% will convert 60% of the fuel it uses into heat, with the remaining 40% lost as exhaust.

In addition to saving money on energy bills, energy efficient boilers also have a positive impact on the environment. The less fuel a boiler needs to use, the less greenhouse gases are emitted into the atmosphere. This is particularly important given the current global concern about climate change. Therefore, choosing a more energy efficient boiler can not only save you money in the long run, but also contribute to a more sustainable future.

Overview of the types of boilers available on the market

There are several different types of boilers available on the market, each with its own unique characteristics and benefits. These include:

- Combination or Combi Boilers: These are the most popular type of boiler in the UK. They are compact and efficient, providing both central heating and hot water on demand, without the need for a separate hot water tank. They are also easy to install and maintain, making them a great option for smaller homes or those with limited space.

- System Boilers: These boilers are similar to combi boilers, but they do require a separate hot water cylinder. This allows for a larger hot water storage capacity, making them a good option for homes with high hot water demands, such as those with multiple bathrooms. They also have a compact design, which means they don’t take up as much space as traditional boilers.

- Regular or Conventional Boilers: These boilers are the most traditional type of boiler and are typically found in older homes. They are separate from the hot water cylinder, which means that they can provide a large amount of hot water and heating at the same time. However, they tend to be larger and less energy efficient than combi and system boilers.

- Biomass Boilers: these boilers use renewable energy sources, such as wood chips, pellets, and logs, to provide heat. They are an environment-friendly option to traditional boilers and they can also be used in combination with solar thermal systems.

- Electric Boilers: are also an option, they are easy to install and have low running costs, however they require a good source of electricity and they may not be as efficient as the other options in terms of heating large properties.

When choosing a boiler, it’s important to consider your specific needs and the characteristics of your home. A smaller home with limited space may be best suited for a combi boiler, while a larger home with high hot water demands may benefit from a system boiler. It’s also worth considering your budget, as some types of boilers may be more expensive to purchase and install. Consulting with a professional plumber is always a good idea to get the best advice for your specific case.

Condensing Boilers

Explanation of condensing boilers and how they work

Condensing boilers are a type of boiler that are designed to extract more heat from the combustion process than traditional boilers. They work by using a heat exchanger to extract additional heat from the water vapor produced during the combustion process, which results in greater energy efficiency.

In a traditional boiler, the combustion process produces hot gases that are vented out through the flue. These gases typically have a temperature of around 150-200 degrees Celsius. In a condensing boiler, the hot gases pass through a heat exchanger, where they come into contact with a cooler surface. This causes the water vapor in the gases to condense, releasing additional heat in the process. This additional heat is then used to heat the water in the central heating system, resulting in a higher overall energy efficiency.

Condensing boilers typically have an energy efficiency rating of over 90%, which is significantly higher than traditional boilers. This means that they are able to convert more of the fuel they use into heat, and less is wasted as exhaust. This results in significant energy savings and lower heating costs for the homeowner.

One of the key features of condensing boilers is that they have a secondary heat exchanger, which is designed to recover heat from the flue gases that would be otherwise wasted in traditional boilers. This secondary heat exchanger is able to extract heat from the flue gases, which is then used to heat the water in the central heating system, resulting in a higher overall energy efficiency.

Condensing boilers also have a modulating burner, which means that it can adjust the amount of fuel it burns based on the heat demand, resulting in even greater energy savings.

It’s important to note that condensing boilers require proper installation and maintenance, if not they may not work to their maximum efficiency and could even damage the system. Therefore, it is recommended to consult with a professional plumber when considering the installation of a condensing boiler.

Comparison of energy efficiency ratings for condensing boilers vs. non-condensing boilers

The energy efficiency of a boiler is typically measured by its annual fuel utilization efficiency (AFUE) rating. This rating is a standard measurement used to indicate how much of the fuel used by the boiler is turned into heat.

Condensing boilers typically have an AFUE rating of 90% or higher, which means that they are able to convert 90% or more of the fuel they use into heat. This is significantly higher than non-condensing boilers, which typically have an AFUE rating of around 80%. This means that non-condensing boilers are only able to convert 80% of the fuel they use into heat, with the remaining 20% lost as exhaust.

For example, a non-condensing boiler with an AFUE rating of 80% would waste 20% of the fuel it uses, while a condensing boiler with an AFUE rating of 90% would waste only 10%. This translates into significant energy savings for the homeowner over time, as well as a lower environmental impact.

It’s important to note that the AFUE rating is a seasonal average, which means that it takes into account the boiler’s performance over an entire heating season and it doesn’t reflect the boiler’s performance during peak usage hours, when the boiler may not be operating at its peak efficiency.

Another important aspect to consider is that the energy efficiency of a boiler not only depends on the type of boiler but also on how well it’s been installed and maintained. A non-condensing boiler that has been installed and maintained properly can have a similar energy efficiency as a condensing boiler that hasn’t been installed and maintained properly.

In summary, condensing boilers have a higher energy efficiency rating than non-condensing boilers, typically above 90% which means that they convert more of the fuel they use into heat and waste less as exhaust. It’s important to keep in mind that the energy efficiency of a boiler also depends on the installation and maintenance of the system.

Discussion of modulating burners and their impact on energy efficiency

Modulating burners are a feature found in many modern condensing boilers that can help improve energy efficiency. A modulating burner is a device that controls the amount of fuel that is burned in the boiler based on the heat demand. This allows the boiler to adjust its output to match the heating requirements of the home, resulting in greater energy efficiency.

When a home’s heating demand is low, a modulating burner reduces the amount of fuel that is burned, which in turn reduces the amount of energy that is used. Conversely, when the heating demand is high, the modulating burner increases the amount of fuel that is burned, providing more heat to the home. This ensures that the boiler is always operating at the optimal level, which results in greater energy efficiency.

Modulating burners also help to improve the overall comfort level in the home by maintaining a consistent temperature. This means that the boiler is not constantly turning on and off to try and maintain a certain temperature, which can cause temperature fluctuations and drafts.

Modulating burners are also able to adjust the air/fuel ratio to ensure that the combustion process is as efficient as possible, which also helps to improve energy efficiency.

In summary, modulating burners are a feature found in many modern condensing boilers that can improve energy efficiency by adjusting the amount of fuel that is burned based on the heating demand of the home. This ensures that the boiler is always operating at the optimal level, which results in greater energy efficiency and improved comfort level in the home.

Types of Condensing Boilers

Overview of different types of condensing boilers (combi, system, regular)

There are several different types of condensing boilers available on the market, each with its own unique characteristics and benefits. These include:

- Combi Condensing Boilers: These are a type of condensing boiler that provide both central heating and hot water on demand, without the need for a separate hot water tank. They are compact, efficient and easy to install, making them a great option for smaller homes or those with limited space. They are also ideal for homes that have a low hot water demand, as they only heat the water when it’s needed.

- System Condensing Boilers: These boilers are similar to combi boilers, but they do require a separate hot water cylinder. This allows for a larger hot water storage capacity, making them a good option for homes with high hot water demands, such as those with multiple bathrooms. They also have a compact design, which means they don’t take up as much space as traditional boilers.

- Regular or Conventional Condensing Boilers: These boilers are the most traditional type of condensing boilers. They are separate from the hot water cylinder, which means that they can provide a large amount of hot water and heating at the same time. They are typically found in older homes and are less energy efficient than combi and system boilers, however, they can be a good option for homes with high heating and hot water demand.

It’s important to note that all these types of condensing boilers have high energy efficiency ratings, typically above 90%, which means they convert more of the fuel they use into heat and waste less as exhaust.

When choosing a condensing boiler, it’s important to consider your specific needs and the characteristics of your home. A smaller home with limited space may be best suited for a combi condensing boiler, while a larger home with high hot water demands may benefit from a system condensing boiler. Regular or conventional condensing boilers can be a good option for homes with high heating and hot water demand. It’s also worth consulting with a professional plumber to get the best advice for your specific case

Pros and cons of each type

Combi Condensing Boilers:

Pros:

- They are compact and space-saving, making them ideal for smaller homes or those with limited space.

- They provide both central heating and hot water on demand, without the need for a separate hot water tank.

- They are easy to install and maintain.

- They are energy efficient, typically with an AFUE rating of 90% or higher.

- They only heat the water when it’s needed, which can save energy and money.

Cons:

- They have a limited hot water flow rate, which means that they may not be suitable for homes with high hot water demands, such as those with multiple bathrooms.

- They may not be suitable for homes with high heating demands, as they may not be able to provide enough heat.

System Condensing Boilers:

Pros:

- They have a larger hot water storage capacity, making them a good option for homes with high hot water demands, such as those with multiple bathrooms.

- They are compact and space-saving, making them ideal for smaller homes or those with limited space.

- They are energy efficient, typically with an AFUE rating of 90% or higher.

- They provide both central heating and hot water on demand.

Cons:

- They require a separate hot water cylinder, which takes up additional space.

- They may not be suitable for homes with low hot water demands, as the cylinder may not be fully utilized.

Regular or Conventional Condensing Boilers:

Pros:

- They can provide a large amount of hot water and heating at the same time.

- They are typically found in older homes and can be a good option for homes with high heating and hot water demand.

- They are energy efficient, typically with an AFUE rating of 90% or higher.

Cons:

- They tend to be larger and take up more space than combi and system boilers.

- They require a separate hot water cylinder, which takes up additional space.

- They may not be as energy efficient as combi and system boilers.

It’s important to note that the suitability and the energy efficiency of a boiler not only depends on the type of boiler but also on how well it’s been installed and maintained, it’s always a good idea to consult with a professional plumber to get the best advice for your specific case.

Recommendations for different types of homes/families

When choosing a boiler, it’s important to consider the specific needs and characteristics of your home and family. Here are some recommendations for different types of homes and families:

For small homes or those with limited space: Combi condensing boilers are a great option as they are compact and space-saving. They provide both central heating and hot water on demand, without the need for a separate hot water tank. They are also easy to install and maintain, making them a convenient option for those who want a hassle-free heating system.

For homes with high hot water demands, such as those with multiple bathrooms: System condensing boilers are a good option as they have a larger hot water storage capacity. They are also compact, energy efficient and provide both central heating and hot water on demand.

For homes with high heating and hot water demands: Regular or conventional condensing boilers can be a good option as they can provide a large amount of hot water and heating at the same time. They are typically found in older homes, they are energy efficient and have a larger hot water storage capacity.

For homes that are environmentally conscious: Biomass condensing boilers use renewable energy sources, such as wood chips, pellets, and logs, to provide heat. They are an environment-friendly option to traditional boilers and they can also be used in combination with solar thermal systems.

It’s important to note that the suitability of a boiler not only depends on the type of boiler but also on how well it’s been installed and maintained.

Choosing the Right Boiler

Factors to consider when choosing a boiler

When choosing a boiler, there are several factors to consider to ensure that you select the right one for your home. These include:

- Size: The size of your home and the number of rooms will determine the size of the boiler you need. A larger home with more rooms will require a larger boiler to provide sufficient heat and hot water. It’s important to choose a boiler that is appropriately sized for your home to ensure that it can meet your heating and hot water demands.

- Fuel type: Boilers can be powered by a variety of fuel types, including natural gas, propane, oil, and electricity. Each fuel type has its own unique characteristics and costs, so it’s important to consider which one is most appropriate for your home and budget.

- Energy efficiency: The energy efficiency of a boiler is typically measured by its annual fuel utilization efficiency (AFUE) rating. This rating is a standard measurement used to indicate how much of the fuel used by the boiler is turned into heat. The higher the AFUE rating, the more energy efficient the boiler is, and the less fuel it will need to use to produce the same amount of heat.

- Size of hot water storage tank: if you have a high hot water demand, it’s important to consider the size of the hot water storage tank, some types of boilers have a built-in storage tank, while others have a separate one.

- Cost: The cost of a boiler can vary significantly depending on the type and size of the boiler, as well as the fuel type. It’s important to consider the upfront cost of the boiler as well as the long-term costs, such as fuel usage and maintenance.

- Modulating burner: as mentioned before, a modulating burner can help improve energy efficiency by adjusting the amount of fuel that is burned based on the heating demand of the home.

- Brand reputation and warranty: Look for a brand that has a good reputation and offer a warranty on their products. A good warranty can provide peace of mind and protection against any potential issues or defects with the boiler. It’s also a good idea to read reviews from other customers to get an idea of the overall performance and reliability of the boiler.

- Professional installation and maintenance: It’s important to have the boiler installed by a professional and licensed plumber to ensure that it is done correctly and safely. Regular maintenance can also help to keep the boiler running efficiently and extend its lifespan.

- Compatibility with other systems: If your home already has other systems in place, such as solar thermal or underfloor heating, it’s important to consider if the boiler you choose is compatible with these systems.

- Future needs: Consider your future needs, if you plan on expanding your family or if you’re planning on remodeling your home in the near future, you may need a boiler that can accommodate those changes.

How to determine the right size boiler for your home

Determining the right size boiler for your home is essential to ensure that it can meet your heating and hot water demands. The right size boiler will also help to ensure that it runs efficiently and can help to keep your energy costs down. Here are some steps to help you determine the right size boiler for your home:

- Measure the square footage of your home: The size of your home will have a direct impact on the size of the boiler you need. The larger your home, the more heating capacity you will need. Measure the square footage of your home, including the basement and attic, to get an idea of the size of the boiler you will need.

- Consider the number of rooms and occupants: The number of rooms and occupants in your home will also impact the size of the boiler you need. A larger home with more rooms and occupants will require a larger boiler to provide sufficient heat and hot water.

- Assess your heating and hot water demands: Consider your specific heating and hot water demands, such as the number of bathrooms and the size of your hot water tank. A home with multiple bathrooms and a large hot water tank will require a larger boiler to meet these demands.

- Consider the insulation and the age of your home: An older home or one with poor insulation will require a larger boiler to provide sufficient heat. A well-insulated home with newer windows and doors will require a smaller boiler.

- Consult with a professional: A professional plumber or heating contractor can help you determine the right size boiler for your home by taking into account all of these factors and by performing a heat loss calculation that will take into account the specific characteristics of your home.

Tips for getting the most out of your energy-efficient boiler

An energy efficient boiler can help to lower your energy costs and reduce your carbon footprint. Here are some tips to help you get the most out of your energy efficient boiler:

- Schedule regular maintenance: Regular maintenance is important to ensure that your boiler is running at its optimal level. A professional plumber or heating contractor can check for any issues and perform any necessary repairs or adjustments to keep your boiler running efficiently.

- Insulate your home: Insulating your home can help to reduce heat loss and make your boiler more efficient. Insulate your walls, attic, and floors to keep heat in and reduce the amount of energy your boiler needs to use to heat your home.

- Use a programmable thermostat: A programmable thermostat can help you to control the temperature of your home more effectively. You can set it to lower the temperature when you’re not at home or when you’re asleep, which can help to reduce your energy costs.

- Seal drafts: Check your home for drafts and seal any gaps or cracks in the walls, floors, and windows to prevent heat loss. This can help to reduce the amount of energy your boiler needs to use to heat your home.

- Use low-flow showerheads: Low-flow showerheads can help to reduce the amount of hot water your boiler needs to produce, which can help to lower your energy costs.

- Use the right size boiler: As explained before, using the right size boiler for your home is essential to ensure that it can meet your heating and hot water demands and run efficiently.

- Adjust the boiler’s settings: Adjust the boiler’s settings to match your heating and hot water demands, you can lower the temperature of the water that is being heated and make the boiler work less to maintain the desired temperature.

Conclusion

In this article, we discussed the most energy-efficient boilers on the market and how to choose the right one for your home. We highlighted the importance of energy efficiency when choosing a boiler, as boilers with high energy efficiency ratings convert more of the fuel they use into heat and waste less as exhaust. We provided an overview of the types of boilers available on the market, including combi, system, regular or conventional boilers and biomass boilers. We also explained how condensing boilers work and the comparison of energy efficiency ratings for condensing boilers vs non-condensing boilers. We discussed the impact of modulating burners on energy efficiency and how they help to improve the overall comfort level in the home. We covered the pros and cons of each type of boiler and provided recommendations for different types of homes and families. We discussed the factors to consider when choosing a boiler, including size, fuel type, energy efficiency, size of hot water storage tank, cost, brand reputation and warranty, professional installation and maintenance, compatibility with other systems, and future needs. We discussed how to determine the right size boiler for your home, by measuring the square footage of your home, considering the number of rooms and occupants, assessing your heating and hot water demands, considering the insulation and the age of your home, and consulting with a professional. Lastly, we provided tips for getting the most out of your energy-efficient boiler, such as scheduling regular maintenance, insulating your home, using a programmable thermostat, sealing drafts, using low-flow showerheads, using the right size boiler, and adjusting the boiler’s settings.

When choosing a boiler, it’s important to research and make an informed decision to ensure that you select the right one for your home. A boiler is a significant investment, and it’s essential to choose one that is appropriately sized, energy efficient, and compatible with your home’s heating and hot water demands.

if you need a boiler installed our gas-safe boiler installation experts are here to help

For more info and tips check out our guide to central heating systems

The post Why energy efficiency matters for homeowners when choosing a boiler appeared first on Heat Quick Direct.

]]>The post Preventing blocked drains: Common causes and tips appeared first on Heat Quick Direct.

]]>What Are Blocked Drains And Why Are They A Problem?

Blocked drains are a common plumbing issue that can cause a range of problems in your home. A blocked drain is a pipe that is partially or completely blocked, preventing water and waste from flowing through it properly.

Blocked drains can be caused by a variety of things, including hair, soap scum, grease, and even tree roots. They can occur in any type of drain, including those in the kitchen, bathroom, or basement.

The Consequences of Blocked Drains

Blocked drains can lead to a range of problems, including:

- Slow-draining or clogged sinks, showers, and toilets

- Water backing up into the home, leading to flooding and water damage

- Foul odors emanating from the drain

- Damage to the pipes due to the pressure of backed-up water

In addition to being inconvenient, blocked drains can also be costly to fix. That’s why it’s so important to prevent them from happening in the first place.

Common Causes of Blocked Drains

There are several common causes of blocked drains. Here are a few to be aware of:

- Hair: Hair is one of the most common causes of blocked drains, especially in the bathroom. It can easily accumulate in the drain and create a blockage over time.

- Soap scum and grease: These substances can build up in your pipes and create a blockage. Grease can harden as it cools, making it particularly difficult to remove.

- Tree roots: Tree roots can grow into and block your drain pipes, especially if they are damaged or cracked.

- Flushing inappropriate items down the toilet: Only human waste and toilet paper should be flushed down the toilet. Flushing other items, such as feminine hygiene products, baby wipes, and paper towels, can lead to blocked drains.

How to Prevent Blocked Drains

Fortunately, there are several steps you can take to prevent blocked drains in your home. Here are a few simple tips:

- Use a hair catcher in the shower or bath: A hair catcher is a small device that fits over the drain and catches hair before it can go down the drain. This can help prevent clogs and save you the hassle of having to clean out the drain regularly.

- Properly dispose of grease and oil: Instead of pouring grease and oil down the drain, let it cool and solidify in a container before disposing of it in the trash.

- Keep trees trimmed away from your drain pipes: Overgrown tree roots can cause damage to your drain pipes and lead to blockages. Be sure to keep your trees trimmed and away from your pipes to prevent this issue.

- Only flush toilet paper and human waste down the toilet: Be sure to only flush toilet paper and human waste down the toilet to prevent blockages.

Conclusion

Blocked drains can be a major inconvenience and can lead to costly repairs. By being aware of the common causes of blocked drains and taking steps to prevent them, you can save yourself the hassle and expense of dealing with this common plumbing issue.

If you are experiencing problems with blocked drains Heat Quick Direct can help

The post Preventing blocked drains: Common causes and tips appeared first on Heat Quick Direct.

]]>The post Renewable heating options appeared first on Heat Quick Direct.

]]>Renewable heating options in the UK explained

As concerns about climate change and the need for a sustainable living continue to grow, more and more people are looking for ways to reduce their carbon footprint and switch to renewable energy sources. One area where this is particularly relevant is in the way we heat our homes. In the UK, the majority of domestic energy consumption is used for heating, making it a key area for consideration when it comes to sustainability. In this article, we will explore the various renewable heating options available in the UK, including solar thermal, air source heat pumps, and ground source heat pumps. We will also discuss the benefits and drawbacks of each option, as well as the potential cost savings and environmental impacts. Whether you’re looking to reduce your reliance on fossil fuels or simply save money on your energy bills, this article will provide valuable information on the renewable heating options available in the UK.

Heat Pumps

Heat pumps are a type of renewable energy system that can be used for heating and cooling buildings. They work by transferring heat from one place to another, rather than generating heat directly like a traditional heating system. There are two main types of heat pumps: air source heat pumps and ground source heat pumps.

Heat pumps are a highly efficient and environmentally friendly way to heat and cool buildings. They can save up to 50-70% on energy bills compared to traditional heating systems, and they produce very low carbon emissions. They are also easy to maintain and have a long lifespan. However, they can be more expensive to install than traditional heating systems, and they may not be suitable for all buildings or climates.

Air source heat pumps

Air source heat pumps use the air outside a building to heat or cool the interior. They work by extracting heat from the air and transferring it inside, or by absorbing heat from inside a building and releasing it outside. Air source heat pumps are relatively easy to install and can be used in both new and existing buildings.

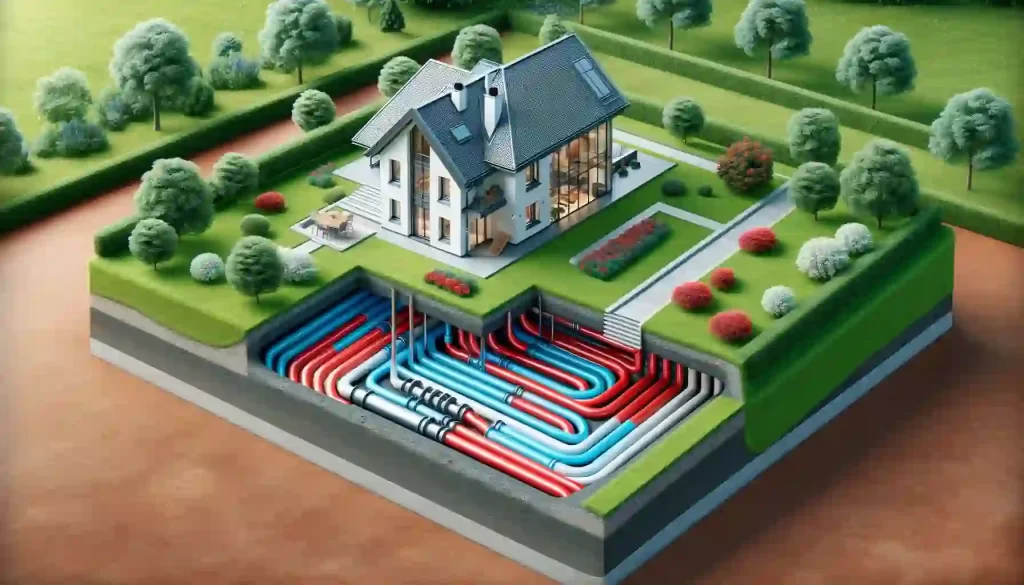

Ground source heat pumps

Ground source heat pumps, also known as geothermal heat pumps, use the ground or ground water as a source of heat. They work by extracting heat from the ground or ground water and transferring it into a building, or by absorbing heat from inside a building and releasing it into the ground. Ground source heat pumps require a ground loop, which can be installed through horizontal trenches, vertical boreholes, or a pond or lake. They are generally more efficient than air source heat pumps and can be used in both new and existing buildings.

Biomass boilers

Biomass boilers are a type of heating system that use organic materials, such as wood chips, wood pellets, or logs, as fuel. These boilers are designed to burn the fuel in a controlled and efficient manner, producing heat that can be used to heat a building or hot water. Biomass boilers are a renewable energy source, as they use a sustainable fuel that can be replenished.

There are several benefits to using biomass boilers. They are a renewable energy source, they can save up to 30% on energy bills compared to traditional heating systems, and they produce low carbon emissions. Biomass boilers are also flexible, as they can be used to heat a building or produce hot water. However, there are also some drawbacks to consider, including the initial cost, the need for fuel storage, and the requirement for regular maintenance. The cost of a biomass boiler depends on the size of the system, the type of boiler, and the fuel used, with prices ranging from £9,000 to £20,000.

Solar water heating systems

Solar water heating systems use the energy from the sun to heat water for domestic use. These systems consist of solar panels, called collectors, which are installed on the roof or walls of a building. The collectors absorb the energy from the sun and transfer it to a fluid, which is circulated through the collectors and into a storage tank. The heat from the fluid is then transferred to the water in the storage tank, raising the water temperature.

There are two main types of solar water heating systems: passive systems and active systems. Passive systems use natural convection to circulate the fluid through the collectors and into the storage tank, while active systems use a pump to circulate the fluid. Active systems are more efficient than passive systems, but they are also more expensive to install.

Solar water heating systems are a highly efficient and environmentally friendly way to heat water for domestic use. They can save up to 70% on water heating costs, and they produce no carbon emissions. They are also easy to maintain and have a long lifespan. However, they may not be suitable for all locations, as they require a south-facing roof or wall with sufficient sunlight. Solar water heating systems can also be more expensive to install than traditional water heating systems, although the initial cost can be offset by the energy savings.

Heat networks

Heat networks, also known as district heating systems, are a type of heating system that uses a central plant to produce heat, which is then distributed to multiple buildings through a network of underground pipes. Heat networks can use a variety of energy sources, including natural gas, renewable energy, and waste heat from industrial processes, to produce the heat.

Heat networks have several benefits, including energy efficiency, cost savings, and low carbon emissions. They are also easy to maintain and have a long lifespan. However, there are also some drawbacks to consider, including the initial cost of installation and the need for a central plant. Heat networks may also not be suitable for all locations, as they require a sufficient demand for heat in the area.

Heat networks are becoming increasingly popular as a way to heat buildings in a more sustainable and efficient manner. They are particularly useful in urban areas, where there is a high demand for heat and limited space for individual heating systems. Heat networks can be used to heat a variety of buildings, including residential, commercial, and industrial.

In conclusion, there are many renewable heating options available in the UK that can provide a more sustainable and cost-effective way to heat buildings. Options such as heat pumps, biomass boilers, solar water heating systems, and heat networks can all use renewable energy sources or waste heat to produce heat, reducing reliance on fossil fuels and reducing carbon emissions. While these options may have a higher initial cost compared to traditional heating systems, they can save homeowners money on energy bills in the long run and contribute to a more sustainable future. It is important to carefully consider the different options and choose the one that best fits the needs and circumstances of the building.

if you need a boiler installed our gas-safe boiler installation experts are here to help

For more info and tips check out our guide to central heating systems

Renewable Heat Incentive Scheme for London Residents

Ground Source Heat Pump Systems Explained for London Residents

The post Renewable heating options appeared first on Heat Quick Direct.

]]>The post Gas safety regulations for homeowners appeared first on Heat Quick Direct.

]]>Guide to the Gas Safety Regulations

The Gas Safe Register replaced CORGI registration in 2009 and all registered engineers must display their unique registration number when working with gas installations or appliances.

Gas safe regulations are put in place to ensure that people’s homes are safe from potential risks associated with using gas, such as carbon monoxide poisoning and fires. All gas installers must be registered with the Gas Safe Register before they can start work on any appliance that uses natural or liquefied petroleum (LPG) gas. In addition, it is legally required for landlords to have an annual safety check by a qualified engineer for any rental property containing a gas heating system or appliance.

Why are gas-safe regulations important?

Gas safety regulations are very important in the UK to ensure gas appliances and equipment are safe for use. Gas is one of the most commonly used sources of energy in homes throughout the country, providing heat and hot water amongst other things. That is why it is so vital that these items are properly checked and maintained by a qualified professional.

The main purpose of gas safety regulations is to reduce the risks associated with using gas appliances, such as risk of fire or carbon monoxide poisoning. All landlords have a legal responsibility to make sure their properties meet the required standards and have annual checks carried out by a registered Gas Safe engineer. This ensures all installations, maintenance, repairs and replacement work meets safety requirements – reducing both public health risks as well as any financial losses related to property damage or personal injury.

What the gas safe regulations cover

The Gas Safe regulations outline a series of rules that must be followed when it comes to any works carried out with gas appliances and installations, including repairs, servicing, maintenance and installation. These regulations apply to both domestic and commercial premises, ensuring all users of gas services stay safe whilst in their homes or workplaces. Furthermore, these regulations also require all engineers working on gas appliances to be registered with the Gas Safe Register – an official list containing details of qualified engineers who are competent for specific types of work.

Gas safe regulations relating to a safe installation

It must be made sure that any new appliance installations meet current safety requirements and legislation. All registered engineers must be able to demonstrate knowledge of their trade with the appropriate qualifications, as well as being up-to-date with the latest industry standards. The engineer is also required to make a check on each type of appliance installed or serviced – this includes checking for potential hazards such as leaks or incorrect pressure settings.

Gas Safety Regulations also require an annual inspection of each installation or appliance by a registered engineer, so that any faults can be identified immediately before they become more serious problems.

Gas safe regulations on Pipework installation

Gas-safe registered engineers are responsible for the installation, maintenance and repair of all pipework systems that use combustible gases in the UK. All professional engineers must be registered with Gas Safe before they can work on any pipework system using combustible gases. Before any work is carried out, engineers must check the design and condition of the pipes, fittings and other components of the system. They will also ensure that all component parts are compatible with each other for safety reasons.

In addition to these safety checks, engineers must make sure that all joints are fitted correctly and securely, as well as make sure there is no leakage from any part of the system.

Gas safe regulations on Moving gas fittings

In order to move a gas fitting, a registered engineer must assess the situation prior to any work being carried out. This includes making sure that there are no existing faults or potential risks with the existing fitting as well as ensuring that all of the necessary safety checks have been made. The engineer will then be able to advise on what needs to be done in order for the fitting to be safely moved.

Once any required repairs or alterations have been completed, the engineer will issue a Gas Safe Certificate which confirms that all of the necessary safety checks have been carried out and that it is safe for use.

Gas safe regulations on Access to the boiler

In order for a boiler to be deemed safe, it must be installed in such a way that there is easy access for maintenance and inspection of its parts. Good access also allows for any necessary repairs or replacements to take place quickly and safely. All gas-related installations must comply with Building Regulations which state that all boiler rooms should have an appropriate size door which allows easy access from either side of the room without obstruction so that service engineers can easily enter without risk of injury or damage.

Gas safe regulations on Room-sealed boilers

The gas safety regulations regarding room-sealed boilers are an important aspect of maintaining public health and safety. Room-sealed boilers are those that are sealed off from their immediate environment, meaning that any leakage of potentially hazardous gases is contained within the appliance itself. This type of boiler must be installed by a competent Gas Safe Registered engineer to ensure that it operates safely and efficiently.

Under these regulations, all new or replacement room-sealed boilers must meet certain standards to ensure they function correctly and provide adequate levels of safety for users. This includes ensuring proper ventilation is provided for combustion air intake, as well as inspecting for flue gases during installation and carrying out a pressure test to verify correct operation.

Gas safe regulations on suspended appliances

When it comes to boilers fitted on the wall or suspended appliances, the HSE has several requirements that must be followed in order to ensure safety. All suspended appliances must be securely fastened so they don’t become loose over time due to vibration or other forces. They must also be accessible for maintenance and repairs, with minimum clearance of 450mm around each side and 300mm above the highest point of the appliance. Lastly, there should be no combustible materials within 600mm of flue outlets or air intakes.

Gas safe regulations on Testing after installation

Testing after installation is a critical step in ensuring that all gas-powered appliances operate safely in homes and businesses around the UK. The Gas Safe Regulations stipulate that any new appliance must be tested by a qualified engineer before it is put into use or connected to other gas services. This includes a wide range of checks to make sure the appliance is installed correctly and will function without causing harm or danger due to leaks, inadequate ventilation or incorrect operation.

landlord’s responsibility under gas safe regulation

The main responsibility of a landlord when it comes to gas safety is to make sure that all gas appliances and flues in the property are safe and working properly. They must also provide tenants with a copy of the Gas Safety Record before they move into their new home, which will show that all necessary checks have been done. Furthermore, landlords must provide tenants with information on how to recognise potential dangers related to gas safety and advise them on what steps should be taken if any issues arise. Any changes or repairs needed should also be carried out promptly by qualified professionals who are Gas Safe registered.

In conclusion

It is important to be aware of the Gas Safety Regulations and to conduct regular checks of your gas appliances. Landlords have a particular responsibility in this regard, as they may need to provide proof that gas safety checks are being conducted on a regular basis. By following these regulations, landlords can provide their tenants with a safe and secure living environment. The consequences of not adhering to the Gas Safety Regulations can potentially be severe, with fines or even imprisonment possible in extreme cases.

The post Gas safety regulations for homeowners appeared first on Heat Quick Direct.

]]>The post Hello world! appeared first on Heat Quick Direct.

]]>The post Hello world! appeared first on Heat Quick Direct.

]]>The post How to use boiler thermostats and controls appeared first on Heat Quick Direct.

]]>Thermostats and Controls

Thermostats and temperature controls not only make it easier to use your boiler, they can also help you lower your heating bill. Plus, time and temperature controls are also integral to modern central heating systems thanks to Boiler Plus legislation.

There is quite a bit of confusion regarding the operation of central heating controls, particularly because of the multitude of types and models made available. From boiler timers to programmable thermostats, we have listed some of the most common heating controls and what usage they can perform for you.

What are the benefits of central heating controls

A variety of boiler temperature controls exist, each with its own beneficial traits. It’s important to learn the differences and how they benefit your home.

- Lower energy bills

- Smaller carbon footprint

- Only heat rooms or areas that need warming up rather than the whole property

- Schedule the heating to come on when you need it and turn off when you don’t

By simply turning your thermostat down one degree you may end up saving £80 on your energy bill annually, which can also equate to a reduction of over 300 kg from your carbon footprint.

Central heating controls explained

A survey showed that 800,000 UK homes (4%) don’t have central heating controls, while 70% possess a complete set of them. There are several types of thermostats and central heating controls that include:

- Built-in boiler controls

- Boiler timers

- Room thermostats with a dial

- Digital programmable room thermostats

- Smart thermostats

- Thermostatic radiator valves

We will walk you through each type of thermostat and heating control so you can put them to use to optimum effect.

Built-in boiler controls

Your boiler is most likely going to have its own unique controls on the front of it, this is handy If your boiler is easy to reach, but not so convenient if it’s set up in your basement, loft, or garage.

The boiler itself will only have basic controls usually including an on/off switch. Your boiler may also have temperature controls. These will allow you to regulate the temperature that the boiler heats its water to, you can adjust these based on the time of year.

Boiler timers

This mechanical timer allows you to program schedule times that your boiler is activated or deactivated. While boiler timers can be used to set an automatic turning on or off for your boiler, they can not control the temperature. You can set the temperature instead with the use of a thermostat.

You will have adequate control over your boiler if you want it to turn on and off at precisely the exact same time daily. However In the event you wish your boiler to be on and off at varied times throughout the day, a boiler timer would not be sufficient.

Room thermostats with a dial

Thermostats in the room will activate your heating until it reaches the setting you have set. Once the temperature has reached your selected level, the heating will shut off. Room thermostats are installed onto the wall with a circular dial that has a pointer on it, pointing at a temperature that is displayed it.

Thermostats need to have the ability to measure the air temperature around them in such a way as to appropriately maintain room temperature, which is why it is important to keep them free from obstructions like curtains or anything that might block the flow of air.

Digital programmable room thermostats

With a programmable thermostat, you can remotely control your heating unit’s settings, and temperature, via a digital interface. Some model programs will enable you to make separate timetables for weekdays and weekends.

In some of the more advanced options, you will be able to specify a different schedule for every day of the week.

Smart thermostats

Smart thermostats allow you to operate your heating system entirely from your smartphone. While various smart thermostat designs have different features, they generally allow you to program and manage your heating system online. Other features can include:

- Weather responsiveness

- The ability to learn and adapt to your routine

- Geolocation which can recognise when nobody is in the home

Thermostatic radiator valves

Thermostatic radiator valves do not affect the boiler, but they can help maintain the temperature in your rooms at your desired level.

Thermostatic radiator valves manage the flow of warm water through the radiator, thereby decreasing it when the temperature reaches a certain level. Because they monitor the air temperature around them, it’s best not to use radiator covers on radiators with thermostatic valves.

Boiler Plus

A new bill went into effect in 2018 to encourage the efficiency of UK homes. Called Boiler Plus, the law stipulated that all gas and oil boiler installations should include a timing and temperature control feature.

Combi boiler installations will also need one of the following:

- Smart controls

- Weather compensation

- Load compensation

- Flue Gas Heat Recovery

What is weather compensation?

Your boiler can recognize the external temperature and use this as well as its existing settings to control the current status of your home’s temperature. This allows it to operate more efficiently, saving you on energy bills.

What’s load compensation

Load compensation enables the temperature of the water going into the radiators to change as the temperature of the home increases. This, in turn, allows the radiators to become heated less quickly and, overall, saves energy. Because the radiators do not need to be so hot all of the time, this makes heating more efficient.

Flue Gas Heat Recovery

All condensing boilers must have a Flue Gas Heat Recovery System As of April 2005, all new gas boilers are required to be condensing by law. So, if you have had a new boiler fitted since then, it should be a condensing boiler. If you have not had a new boiler fitted since 2005, you may consider installing one.

When to have boiler controls installed?

Updating your already existing temperature controls is a great way to improve your control over the heating in your living space and domestic hot water.

If your present boiler was installed more than eight years ago, now is the time to think about a replacement, and it’s the best time for you to put in new controls so you can benefit from a more efficient heating system. That way, you’ll benefit from a more efficient heating system, and you’ll have the ability to control it more effectively to suit your needs.

If you need thermostat boiler controls installed you can count on the experts at Heat Quick Direct

The post How to use boiler thermostats and controls appeared first on Heat Quick Direct.

]]>The post Ground source heat pump systems explained appeared first on Heat Quick Direct.

]]>Ground Source Heat Pump Systems Explained

A ground source heat pump takes advantage of the heat in the ground to provide your home with reliable heating and hot water. Temperatures underground remain between 10 and 15 degrees Celsius regardless of the time of year, so the system can be utilized all year round.

How ground source heat pumps work

Ground-source heat pumps are composed of 3 different components that work together to transfer heat from the ground into living quarters.

Ground loop

This is a pipe hidden underground, usually underground in the garden, either in a trench or a vertical burrow. A trench goes 2 meters below ground level, while boreholes are drilled deeper down to between 15 and 150 meters. More heat can be retrieved from the ground with longer loops, but available real estate will determine the most suitable area for the extraction of underground heat.

The mixture going around these pipes will be both water and antifreeze. The natural heat from below is absorbed by the fluid, which then goes by way of a heat exchanger to warm a heat pump.

Heat pump

Heated water is passed throughout the house to radiators or underfloor heating systems. If the system is being used to warm water, then the water is sent to cylinders for water storage. A functional Heating system is created when these components are coordinated.

Horizontal trenches and vertical boreholes

The pipes can be installed horizontally or vertically, depending on the space available on your property. Vertical boreholes typically go straight down into the ground and can be as long as 15 – 100 meters. Horizontal systems are shallower but can cover more area. Vertical systems are typically more expensive initially, but they should pay off in the long run.

What is the best heating system for a heat pump?

The heat generated by a ground-source heat pump is best suited to underfloor heating. Radiators usually need to be heated up to about 70 degrees in order to heat rooms, whereas underfloor heating typically operates at 30 degrees. If you’d like radiators as opposed to underfloor heating, you may need to install larger ones.

How efficient are ground source heat pumps?

While they do require electricity, a fully insulated ground-source system can provide roughly 3-4 more kilowatts of energy for every kilowatt of electricity used. That equates to an efficiency of roughly 300 per cent.

Ground source heat pumps can be an efficient and cost-effective method of heating your home, and you may be able to receive government funds to help offset the installation cost.

How to maintain a ground source heat pump

While a ground-source heat pump needs little in the way of upkeep, it’s crucial to watch how it’s functioning. The Ground Source Heat Pump Association suggests that initial safety inspections are not required, though the system should be serviced every five years.

Manufacturers may require their ground-source heat pumps to undergo service maintenance during the warranty period, so always be sure to consult your manufacturer.

How long do ground-source heat pumps last?

The lifespan of a heat pump depends on the kind and how well it continues to be maintained. Some heat pumps may last as long as twenty-five years, but others may need to be replaced after only ten years. Regardless of the heat pump, a ground source heat pump is among the best long-term investments you can make for your house because it can efficiently heat your property for many years.

Is a ground source heat pump right for your home?

First, you’ll need to ensure that your house is of the correct size for a ground source heat pump installation. your house must have enough space in your garden for either a horizontal trench or vertical borehole, and this may require access for various machinery.

It is essential that a well-insulated and draught-free home be utilized to make the most of a ground-source heat pump’s efficiency.

If you need a ground source heat pump installed give us a call or request a call back

The post Ground source heat pump systems explained appeared first on Heat Quick Direct.

]]>The post Tips to lower your heating bills appeared first on Heat Quick Direct.

]]>Boiler Efficiency Explained

Upgrading your boiler to a more efficient model can save you money on your monthly fuel bill. Older, less efficient boilers waste energy and money, while newer models are much more efficient and cost-effective. By upgrading to a new boiler, you can lower your monthly fuel costs and improve the comfort of your home.

What is boiler efficiency?

When it comes to boiler efficiency, there are a few key factors that play into how much heat your home will get for the amount of fuel you put in. One of the most important is the boiler’s ability to turn that fuel into usable energy without wasting any of it. This is determined by various factors, including the boiler’s design and the quality of its construction.

What is ErP?

The Energy Related Products Directive (ErP) is an EU directive that phased out inefficient appliances. The directive sets minimum efficiency standards for products such as boilers, air conditioners, and refrigerators. Products that meet the ErP standards are labelled with an energy efficiency rating from A to G.

Appliances that are not ErP compliant will eventually be phased out and replaced with more efficient models. If you’re shopping for a new boiler, look for one with an A or B energy efficiency rating.

ErP directive applies to heating products in Europe and has two benefits.

- Clear energy labelling allows consumers to choose the most energy-efficient products, reducing carbon emissions and saving money on energy bills.

- The Ecodesign Directive is a European Union directive aimed at increasing the energy efficiency of products. The directive was introduced in 2005 with the aim of reducing greenhouse gas emissions, and it has been amended several times since then. In September 2015, it required that products meet higher energy efficiency standards

Boiler manufacturers and retailers have a responsibility to ensure that their products are accurately labelled. This means that the boiler’s efficiency should be clearly stated so that consumers can make an informed decision about which model to buy. The installer who fits your new boiler is also responsible for ensuring that it is efficient. If you’re not happy with the efficiency of your boiler, you should contact the manufacturer or installer to discuss your options.

What is SEDBUK?

The ErP ratings were introduced to replace the SEDBUK ratings because the ErP ratings are a more accurate way of measuring a boiler’s efficiency. The SEDBUK ratings only measure the efficiency of the boiler when it is in standby mode, while the ErP ratings measure the efficiency of the boiler when it is actually heating your home.

What is Boiler Plus?

Boiler Plus is a government scheme that requires new gas boiler installations to meet certain requirements for increased efficiency. This is designed to help homeowners save money on their energy bills and reduce their carbon emissions.

One of the main benefits of Boiler Plus is that it encourages homeowners to upgrade to more energy-efficient boilers. A newer, more efficient boiler can save you up to £340 a year on your energy bills, so it’s definitely worth considering if your boiler is getting old and inefficient.

Boiler Plus also introduces some new requirements for boilers, such as the need for a carbon monoxide alarm and an automatic shut-off in case of high levels of carbon monoxide. This is a great safety measure that will help to protect you and your family from the dangers of carbon monoxide poisoning.

Overall, Boiler Plus is a great initiative that can help you save money on your energy bills and make your home safer.

The Boiler Plus initiative sets minimum requirements for the efficiency of gas-fired boilers. These requirements must be met in order to sell boilers in the UK. The initiative was introduced in response to the Energy Performance of Buildings Directive, which requires all new buildings to achieve a minimum level of energy performance.

Gas boilers must be at least 92% efficient in order to meet the minimum requirements of the Boiler Plus initiative. However, there are a number of ways to improve your boiler’s efficiency and lower your heating bills.

Benefits of an efficient boiler

Replacing an old, inefficient boiler with a new, more efficient model can result in significant savings on your heating bills. Newer boilers are more efficient at converting fuel to heat, so you’ll use less energy to keep your home warm. Additionally, newer boilers have been designed to produce less pollution, so you’ll be doing your part to help the environment.

ways to make your boiler more efficient

1. Annual boiler service

Having your boiler serviced every year is important to keep it running efficiently. A service can help to spot potential problems and fix them before they become more serious and expensive to repair. It can also improve the efficiency of your boiler, helping to lower your heating bills.

2. Bleed the radiators

Bleeding your radiators is a process of releasing air from the radiator using the bleed valve. This is usually done when the heating system is first installed and then again every two years. If you don’t bleed your radiators, they will eventually become blocked and the energy required to heat your home will be increased.

3. Keep the water pressure topped up

A boiler operates more efficiently with a higher pressure because it is able to create more heat. This is due to the increased thermal energy that is created by the combustion process. The increased pressure allows for a greater volume of gas flow, which helps the boiler reach its optimal operating temperature sooner. Additionally, a higher pressure helps to prevent scale formation on the heat exchanger.

4. Insulate cylinder and pipes

Making sure your property is well insulated is key to keeping your home warm and improving boiler efficiency. This includes insulating the cylinder and pipes, as these are often the areas that lose the most heat. You can also install insulation around your doors and windows, and make sure to seal any cracks or gaps that may let heat escape.

Conclusion

Improving boiler efficiency can save you money on your energy bills and help the environment. There are many ways to make your boiler more efficient, so be sure to explore all of your options. If you’re looking for a new boiler, consider investing in an energy-efficient model that will save you even more money in the long run. Thanks for reading!

If you need an energy efficient boiler installed why not choose one of our expert engineers at Heat Quick Direct

For more info and tips check out our guide to central heating systems

The post Tips to lower your heating bills appeared first on Heat Quick Direct.

]]>The post Replacing radiator valves appeared first on Heat Quick Direct.

]]>How to replace radiator valves

Radiator valves regulate the flow of water from your boiler to your radiator. When they are faulty, they can cause problems with your heating in that area and perhaps throughout the rest of your system.

If you’re unsure how to replace a radiator valve, this article will walk you through each stage. Read on to find out whether it’s broken, defective, or needs to be replaced with a new thermostatic valve.

What exactly are the two valves on a radiator used for?

Radiator valves are used to regulate temperature, working similarly to faucet handles in that they control the amount of water fed into the radiator. You’ll generally have two valves: a “control valve” that controls the flow of water going into the radiator by restricting it, and a “lockshield valve” to balance your system by regulating heat

How to recognize a malfunctioning radiator valve

There are a few warning signals that a radiator valve may be faulty:

- Jammed radiator valve

- A dripping radiator valve

- Your heater isn’t working properly – it might be cold in some places or all over.

- Twisting the radiator’s lower valves has no impact on how much heat it releases.

If your radiator isn’t heating up as quickly as it should, or if it has cold spots, first verify that it needs to be bled. Check out our easy bleeding radiators how-to guide to learn how to bleed radiators, then check your radiator again. If everything is fine, a radiator valve replacement is not required.

How does a radiator valve work?

If you’ve done all of the steps for bleeding a radiator and it’s still not working, and all of your other radiators are functioning properly, it’s time to address the radiator valve.

If you have a shut-off valve on your hot water heater, follow the instructions in the manual. If not, adjust it as needed to meet your requirements and local code restrictions. The procedure for this depends on the type of radiator valve you have.

- Thermostatic radiator valve (TRV)

- A TRV is a device that controls the temperature of your radiators. It has a dial with settings ranging from ‘*’ (off) to 1 (about 10°C) to 5 (about 23°C).

- Manual valve

- This is a less sophisticated form of the modern TRV that can commonly be found on older heating systems. It has just two settings: on/open and off/closed.

- Lockshield valve

- The thermostat is in the opposite position from your TRV or manual valve. It has a smaller plastic cap on it that you can remove and use a spanner to open or close the valve. The lockshield valve is rarely needed.

Thermostatic radiator valve (TRV)

Thermostatic Radiator Valves are the perfect solution for heating individual rooms. Because they allow you greater control over room temperatures, you can save money on utilities in areas that aren’t heavily utilized. Thermostatic Radiator Valves automatically adjust the flow of hot water into your radiator according to air temperature, ensuring that it remains at the desired setting

A TRV is composed of two distinct pieces, known as the “head” and “body.” If the temperature drops or rises more than your predetermined setting, a temperature-sensitive capsule within the head of the TRV will expand or compress, pushing in or pulling out a pin in the body of the valve. This allows for either an opening or

The core of the capsules in TRVs is a metal spring that is filled with wax or liquid. Because the liquid is more sensitive to temperature changes, it’s thought of as the most dependable form when changing temperatures. Wax is generally slower, so it’s less expensive.

Jammed radiator valve

The most prevalent issue with TRVs is when the head of the valve sticks or catches, leaving the radiator open or closed. This can happen if the valve hasn’t been adjusted in months – for example, at the end of a hot summer.

Is the pin sticking up out of the body of the valve? If it’s trapped inside the valve or rigid, a spray of WD40 should do the trick. You can also give the valve a light tap around the outside edges, around the pin, with a hammer if it’s stuck in further. If this does not work and the pin is still trapped within the valve body, try tapping on the actual pin gently to dislodge it, after WD40 has been applied.

It’s possible that the pin is working properly but the wax or liquid capsule in the head of the TRV has failed, necessitating a new valve head.

If the hammer won’t pry open a stuck valve, you’ll need to replace it altogether. You’ll also want to drain your heating system if the pin in the valve won’t budge with the hammer.

Leaky thermostatic radiator valve

Plumbers’ tape can be used to seal a leaking TRV (it’s known as PTFE tape by plumbers).

Begin by turning off or closing the other side’s TRV and lockshield valve. The two compression nuts, one on each side of the radiator, are strong suspects for the leak. It is relatively simple to loosen and seal with PTFE tape the olive-shaped compression fitting on the radiator side.

If the insert’s thread is leaking, you may loosen it to expose as much thread as required. Wrap the PTFE tape around the thread in the same direction as when removing it. Then rewind and tighten the nut and olive once again. To check for leaks, open the valves once more.

Manual valve

The temperature is regulated globally by your thermostat with a manual radiator valve. With fewer moving components, these valves are easier to use.

Leaky manual valve

Leaking glands are the most frequent issue with manual valves. The gland is the location where the valve spindle enters the valve body.

The gland packing is compressed around the spindle by the gland nut, which is the highest nut you can see on the spindle. The packing is compressed when this nut is tightened. However, if you tighten it too much, the spindle will be difficult to turn.

The manual valve’s gland nut may have a previous hard-sealing and internally sealed ‘O’ ring. The gland nut on these valves has no visible thread. When the ‘O’ ring wears down, the valve will leak. If this type of valve leaks, closing it entirely or completely opening it might temporarily stop the leak, but the valve

It’s possible to replace the ‘O’ ring, but removing the gland nut completely is not for the faint-of-heart; on some valves, the spindle may come straight out with a lot of filthy water, so keep towels handy.

Lockshield valve

The lockshield valve is usually encased in a plastic cap that reads “lockshield,” which protects it from being inadvertently altered or banged.

The cap is removed, and the top of the spindle can be seen. You may turn the top of the spindle with a spanner to adjust the amount of water passing through the radiator. The spindle can be flat, square-shaped, or even a half-moon shape.

When you’re balancing your radiators in different rooms of your home, for example, adjusting each radiator until it’s heating at the same rate as the others, you usually just need to adjust the lockshield valve. The lockshield valve is the last barrier standing between you and a furious shower! If your shower isn’t as hot as it should be, check your water pressure.

What do I need to replace a damaged radiator valve?

If your radiator valve is beyond repair, you must replace it. Here’s a list of the equipment you’ll need to do so: n

- Your new valve

- An adjustable spanner or spanner set

- PTFE tape (also called plumber’s tape, typically used to seal pipe threads)

- A wrench

- A hose

- A jubilee clip (a circular metal band or strip designed to hold a hose onto a circular pipe)

- Wire wool

- A dry cloth

- Freezing kit (if you aren’t going to drain your system)

- Plus any additional tools

How to replace a radiator valve

It’s not at all difficult to repair your radiator valve yourself without risking flooding if you use a step-by-step approach like the one outlined in this article. Follow our 8-step procedure in the section below carefully.

1. Drain the system

Before you begin any work on your central heating system, it must be drained.

If you have a combi boiler, follow the instructions below; however, if you have a conventional cylinder tank heating system, you’ll need to get help from your local heating Home Expert.

How to Empty a Combi Boiler Heating System:

- Connect the hose to the drain cock and secure it with the jubilee clip, which is typically found at the bottom of the piping.

- Run the hose outside and open the drain cock.

- Wait until all of the water has fled before proceeding to the next step.

You may also isolate your radiator instead if you can’t drain your system (or choose not to):

- Close the valve you’re not disconnecting.

- To prevent water from flowing, wrap the pipe that connects to the valve you’re removing in a freezing kit. Make sure the heating is turned off; it thaws in approximately 15 minutes.